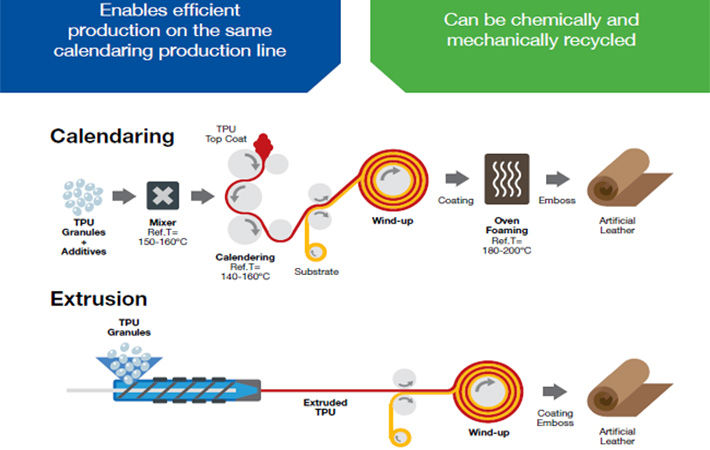

As both calendaring and extrusion production lines can be used to process Elastollan TPU, PVC manufacturers can utilise its existing calendaring line and ‘drop-in’ Elastollan TPU seamlessly and cost-effectively. Additionally, with Elastollan TPU, synthetic leather can be produced without the use of solvents, meeting stringent VOC standards. Elastollan TPU further contributes to sustainable development as it can be recycled mechanically and chemically, BASF said in a media statement.

Elastollan TPU is also appealing for premium applications owing to its excellent soft-touch haptics, which help to enhance the look and feel of end products. Moreover, it is easy to dye and emboss, allowing a variety of colours and designs. It is also a material of choice as it possesses outstanding properties, including high abrasion resistance, hydrolysis resistance, and cold flexibility.

“The drop-in solution enables flexible and efficient processing. PVC manufacturers can now diversify their portfolio to offer both PVC and high-performance TPU. This contributes to sustainable development, as more TPU can be used by PVC manufacturers for the production of synthetic leather,” Marilyn Lye, vice president, business management industrial, performance materials Asia Pacific, BASF said in a statement.

Fibre2Fashion News Desk (GK)