The newly developed fabrics, which incorporate liquid crystalline elastomers (LCEs), a type of intelligent material that reacts to heat, light, or other stimuli, were developed using traditional textile crafting techniques. Developed in the 1980s, LCEs have been used as thin films in soft robotics. Although LCEs have been made into fibres, so far, they haven’t been made into textiles, the two universities said in a joint press release.

The team used conventional textile crafting techniques to develop the smart fabric, testing two versions with soft or rigid LCE yarns. All of the LCE fabrics when kept under an infrared lamp contracted as they warmed up. The changes were reversible as they returned to their original shape once the temperature cooled.

“At first, the impact of using industrial textile techniques with these kinds of new materials wasn’t clear to us. The elasticity of the two types of LCE yarn is comparable to spandex or even softer. That meant it was essential to understand if the textile industry could use these yarns and how the combination with conventional yarns would impact their movement,” said Pedro Silva, project lead and postdoctoral researcher at Aalto.

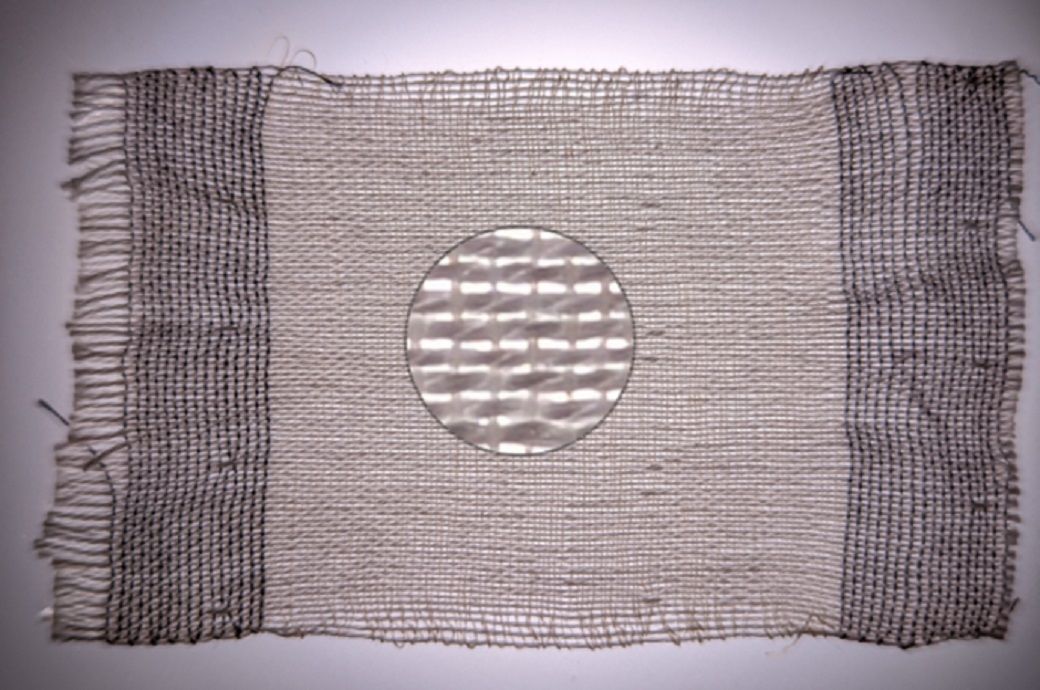

The researchers combined LCE yarns with linen and nylon in a circular pattern to weave a circle that would transform into a cone when heated. When heated, the LCE yarn contracted, causing the pattern to become a cone before returning to its original circular shape. The study’s findings, published in the Advanced Functional Materials journal, show that the technology used in the project can be used in the future to make intelligent fabrics that can adapt to different stimuli, added the release.

The development of this new fabric provides opportunities for the apparel sector with the smart and interactive clothing market projected to be worth $6.5 million by 2028, according to India-based market research firm Coherent Insights.

“From day one of this project, we took on the challenge of working with experts spanning different disciplines at the two institutes. The research succeeded and benefited tremendously from this multi-disciplinarity, and now the results are openly available. We hope our work will trigger new ways of thinking when it comes to the materials of tomorrow,” said Maija Vaara, an Aalto PhD student and project participant.

Fibre2Fashion News Desk (NB)