Theterm quality is somewhat intangible in its definition since it will meandifferent things to different people or even different companies involved inthe manufacture or use of the textile item. One way to assess quality is todetermine its fitness for the end use for which the textile item is being made.For Technical Textiles the test is done to ensure proper performance standardfor the goods. The product checked routinely by sampling and testing throughvarious standard procedures through a process called quality control. A qualityfailure in anything from one of the subassemblies to the final fabric formcould result product being classified as being a poor quality product. For thisreason testing of each component at each stage of the manufacturing process isrequired in order to arrive at a high quality product, containing zero defects.

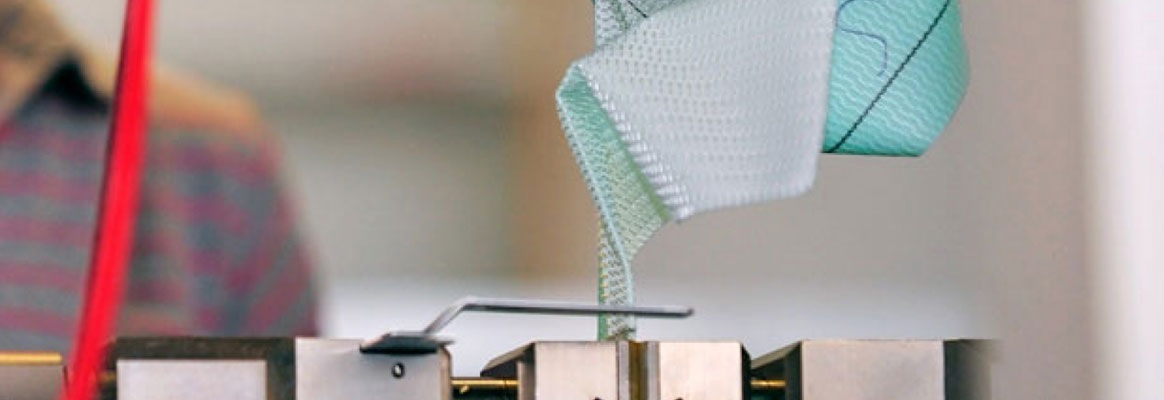

Thematerials used in technical textile products in particular may be in the formof fiber, yarn, fabric (woven, non-woven, knitted or braided) or in the form ofcomposites. Evaluation of both raw materials and the final product is necessaryfor meeting the stringent quality requirements of a technical textile product.

Toread more,

This article was originally published in the Textile Review magazine,October, 2012, published by Saket Projects Limited, Ahmedabad.

About the Authors:

Prof.Mrs. P. M. Katkar is an Assistant Professor at the Department of TextileTechnology, D.K.T.E.S's Textile and Engineering Institute, Ichalkaranji

Govardhana RaoChilukoti is an M.Text from the Department of Textile Technology, D.K.T.E.S'sTextile and Engineering Institute, Ichalkaranji

News

News Articles

Articles Interviews

Interviews Events

Events Advertise with us

Advertise with us About Us

About Us Contact Us

Contact Us Privacy Policy

Privacy Policy Terms & Conditions

Terms & Conditions Cookie Policy

Cookie Policy