ABSTRACT

The hallmark of all Indian festivities is the golden glitter of the sarees and similarly-adorned dresses worn on such occasions. All that glitters may not be gold and the ‘zari’ (metallic yarn), responsible for this lustrous appearance, may or may not contain any gold. This paper reviews the different types of metallic fibres and their production.

INTRODUCTION

Metallic yarns or threads, in general, have been known for more than 3000 years. Gold and silver were hammered into extremely thin sheets, then cut into ribbons and worked into fabrics. These were the first ‘man made’ fibres, which came thousands of years before nylon or rayon. The Persians made fabulous carpets with gold thread and the Indians, ornamental sarees with it. The metal threads were twisted, doubled or wrapped around some other thread such as cotton.

With the advancement of technology, metal/conductive textiles found extensive functional applications. These materials have high electrical conductivity and radar reflecting property, yet are lightweight and flexible. Various methods have been developed to coat fibers and textile materials by metals.

» sputter coating

» coating metal powder with binders

» electro less coating

» vacuum deposition

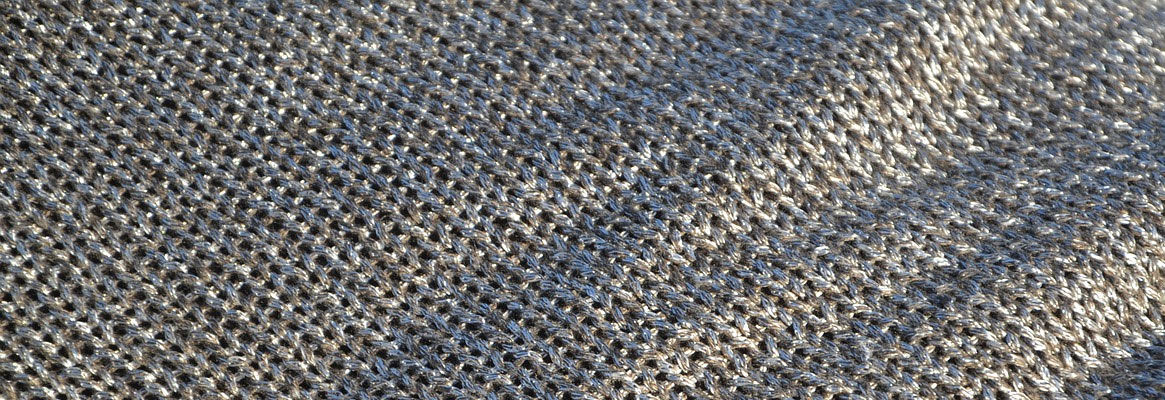

Many technical applications demand properties which cannot be obtained by simply processing common textile material into single textile fabric. However, combination of knitted structure, textile and metal yarn of wire make it possible to create innovative products for multipurpose technical application. Thus knitted fabrics are flexible and extensible and metal wire possess properties which are advantageous in technical textile with regard to their permanent antistatic behavior, known conductivity, shielding from electro magnetic field & resistance to cutting.

METALLIC FIBRE

The term metallic fibre, in its general sense, means simply a fibre that is made from metal. The generic term “metallic” was adopted by the U.S. Federal Trade Commission and is defined as: A manufactured fibre composed of metal, plastic-coated metal, metal-coated plastic, or a core completely covered by metal. Thus, metallic fibres are: fibres produced from metals, which may be alone or in conjunction with other substances.

These metal filaments were made by beating soft metals and alloys, such as gold, silver, copper and bronze, into thin sheets, and then cutting the sheets into narrow ribbon-like filaments. The filaments were used entirely for decorative purposes, providing a glitter and sparkle that could not be achieved by other means.

As textile fibres, these metal filaments had inherent short comings which restricted their use. They were expensive to produce; they tended to be inflexible and stiff, and the ribbon-like cross-section provided cutting edges that made for a harsh, rough handle; they were troublesome to knit or weave, and they had only a limited resistance to abrasion. Apart from gold, the metals would tend to tarnish, the sparkle being dimmed with the passage of time.

Despite these shortcomings, the metallic ribbon-filament has remained in use for decorative purposes right up to the present day. The development of modern techniques of surface-protection has brought cheaper metals into use; aluminium foil, for example, may be anodized and dyed before being slit into filaments which are colourful and corrosion-resistant.

Ribbon-filaments are now manufactured in considerable quantity, e.g. as tinsel, but they remain an essentially decorative material. The filaments are weak and inextensible, and are easily broken during wear; they lack the flexibility that is essential in a genuine textile fibre.

Multicomponent Metallic Filaments

In recent years, the ribbon filament of metal has undergone a transformation, which has changed the commercial outlook, for this ancient product. The metal of the filament is now sandwiched between layers of plastic, which protect it from the atmosphere and from other corrosive influences. The multicomponent filaments produced by slitting sandwich materials of this type are stronger and more robust than the filaments cut from metal foil alone. They retain the glitter of the metal during prolonged periods of use, and have a soft, pleasant handle. Coloured pigments may be added to the adhesive used in sticking the plastic films to the metal foil or metallized film.

Metallic fibres of this type are now widely used in the textile industry, and are produced in a range of colours and forms by many manufacturers. They remain, however, essentially decorative materials and their applications are restricted to this type of use.

Metal-foil and metal-coated yarns are characterised by a flat ribbon-shape with knife-slit edges. Metallic fibres of this type are now widely used in the textile industry and are popularly known as “Lurex” yarn (Trade name).

The main constructions of metallic yarns in order of commercial importance are as follows:

i) Mono ply yarns made from polyester film of 12 or 24 um thickness, metallised and coated both sides either with dear or coloured lacquer (Lurex C 50 and C 100) or with heat and chemical resistant resin-lacquer (Lurex-TE and TE 100). Lurex TE 50 and TE 100 are non-tarnishing and have greatly enhanced resistance to scouring and dyeing treatments of suppleness, brilliance, and yield.

ii) Laminated yarns based on one layer of aluminium foil sandwiched between two layers of 12 um thick polyester film using clear or coloured adhesives (Lurex MF 150). This yarn has higher strength and abrasion resistance.

iii) Mono ply yarns made from 12 um polyester film (transparent - Lurex N 50) or treated with a surface dispersion to give a rainbow effect (Lurex N 50 Irise).

iv) Lurex yarn types C 50, N 50 (Transparent and Irise), and TE 50 can also be obtained supported with two ends of either 17 dtex or 33 dtex monofil nylon. Metallic yarns are usually described in terms of the nominal thickness of the composite film(s) and not the overall thickness of the yarns; the thickness of the resin-lacquer coating or adhesive layer is ignored.

Chemical nature:

The modern and cheap metallic yarn consist of filaments of aluminium covered with plastics: two kinds of plastics are mainly used for the covering. The first and most common is cellulose acetate-butyrate and the second and better is Mylar, DuPont’s polyester film which is chemically similar to Dacron and Terylene. The mixed ester of cellulose with acetic and butyric acids is used more popularly than cellulose acetate, mainly because it has a lower melting point and is more easily worked.

Lurex MM

Lurex MM is different from other varieties of Lurex which consist of a sandwich of aluminium between two films of cellulose acetate-butyrate or Mylar. Lurex MM has a basis of metallised Mylar produced by the vacuum deposition of aluminium on Mylar film. A layer of metallised Mylar is either, (a) bonded to one layer of clear Mylar or (b) sandwiched and bonded to two layers of clear Mylar.

Colour is introduced with the adhesive. The important difference is that the metallic layer in Lurex MM consists of discrete particles and not a continuous ribbon. This construction gives Lurex MM particular softness and thinness, and it affects some other properties, too.

Width and yield:

The ribbon-like shape of metallic yarns makes width an important factor and all Lurex designations bear a width reference. The amount of yarn cover and metallic lustre of a fabric depends upon the width. Lurex is slit to seven standard widths: 1/128, 1/100, 1/80, 1/64, 1/50, 1/32 and 1/16 inch. The 1/64 inch width is established as standard for weaving and knitting yarn. The various types and widths of metallic yarns are not designated by any standard textile yarn numbering system. Yields are in yards per pound.

Gauge:

Metallic yarns are described by width and by gauge. The gauge is the thickness in one hundred thousandths of an inch of the two layers that form the Lurex sandwich. The gauge figure does not indicate total yarn thickness because it does not take into account the adhesive, pigment or the aluminium layer. For e.g., 260 Butyrate Lurex consists of two layers of 0.00130 inch cellulose acetate-butyrate with a 000045 inch aluminium foil and adhesives between its total thickness is 0.003 2 inch, indicating that the two layers of adhesives must each be about 0.0008 inch. A 260 gauge 1/64 inch yarn yields about 10,500 yards per lb. corresponding roughly to about 430 denier, 1 gauge = 0.00001 inch.

Supported Lurex:

When additional strength and/or special effects are desired, Lurex is available in combined form. Most combining yarns are continuous filament yarns: silk, nylon, fortisan, cotton and rayon are commonly used. Combining is usually done on a hollow spindle twister and is carried out in such a way that the metallic yarn remains flat and the supporting yarn wraps around it. The number of turns per inch in the support yarn can vary but usually number 6.

a) All properties are based on 1/64 inch width yarn gold and silver only.

b) Reflectance results are reported from photo volt reflectometer with green filter against an ASTM standard measuring 89.9%.

c) Some ‘whitening’ can occur on Lurex at boil. This is due to a mechanical pick up of water by the bonding adhesive or protective film and may be cleared by drying.

d) Flammability is evaluated on fabrics. Figures reported are typical for Lurex provided that the accompanying fibres and/or finishes do not influence the behavior of Lurex

New developments:

a) Multi-Functional Textiles

b) Sensing yarn, woven/knitted into garments.

c) Intelligent textile applications.

d) Heatable textiles as the heating element.

e) Conductive seam ribbons for Clean room garments.

f) Stimulation electrodes knitted into garments.

g) Weavable /knittable lead wires.

h) Heatable textiles.

i) EMI Shielding wall-coverings and other textile structures.

METAL FIBRE PROPERTIES

Metal Fiber Fineness

Due to its history as a wire drawn product and its abnormally high specific gravity, metal fiber sizes are typically described in terms of their actual diameter in microns as opposed to their linear weight in denier. As an illustration, a single human hair is 70 micron in diameter, and the current working range of bundle drawn stainless steel fibers is from 1- micron diameter to 100-micron diameter. Most textile applications utilize fibers in the range of 8 to 14 microns. As a way of comparison with polyester, a 12-micron metal fiber has the same diameter as a 1.4 denier polyester fibre.

(a) Electrical Conductivity / Electro-Magnetic Shielding

Certainly, the most distinguishing property of metal fibers is its electrical conductivity. When compared on a sq.cm basis, metal fibers can be classified as true conductors. Carbon fibers and anti-static finishes, on the other hand, are electrically classified as Semi-conductors. These differences can be significant in anti-static applications where atmospheric humidity is low and washing durability is an issue. Tests have been run on fabrics with a grid of stainless steel spun yarns where the same anti-static behavior is maintained after more than 200 wash cycles. In Europe it is reported that stainless steel is the only fiber type to consistently exceed EN 1149 after washings.

This high electrical conductivity also leads to good EMI shielding characteristics. Stainless steel fibers have long been utilized as an additive to plastic casings as a way to shield internal components from electromagnetic radiation. As concerns around EMI shielding grow, these conductive plastic applications have expanded a variety of textile applications for metal fibers. Garments, seals, gaskets and wall-coverings are all commercial application areas for shielding fabrics. There is even ongoing research into the possible therapeutic value of such fabrics for various medical treatments.

(B) Heat Resistance and Strength:

Since the early 1990’s a growing market segment for solid metal fibers has developed in the area of industrial, heat-resistant textiles. There exist many industrial environments that operate above the long-term working temperature of fiber glass and aramid fibers. This is especially true in glass forming processes where temperatures can range from 450 to 6000 C. In this particular application, there are other fibers that can withstand these temperatures from decomposition or melting standpoint, but they experience such a significant loss in strength or flexibility, that their resistance to mechanical load dramatically affects the fabric life.

Yet another important attribute to metal fibers is the ability of certain metals to behave in a chemically inert way, regardless of the environment that they are exposed to.

MANUFACTURING BRAND

Metallic yarn of the type discussed here is manufactured by American and French firms under different trade names. Some of these are:-

| Dow Chemical Co. | Lurex |

| Fairtex Corp. | Fairtex |

| Melton Corp. | Melton |

| Reynolds Metals Co. | Re Aluminium |

| Standard Yarn Mills | Lame |

| Sildorex SA,France | Lurex C, Lurex TE. |

Properties:

i) Chemical resistance:

Metallic yarns, although protected at the top and bottom of their flat sides, are vulnerable at their cut sides. However, as the area exposed is small, tarnishing due to atmospheric exposure is negligible. Chemical attack is serious only if the chemical is one that dissolves aluminium. Any of the Lurex yarns, if immersed in caustic soda, loses metal due to the aluminium dissolving in caustic soda through the cut side of the yarn. Lurex MM is unaffected by 2% hydrochloric acid at 99°C for 2 hours whereas Lurex MF loses metal.

ii) Strength:

Strength of the acetate - butyrate Lurex yarn is not very high, but is sufficient to enable it to be used as warp or weft unsupported. The Mylar coated yams are much stronger because of the strength of the polyester film. They can be used for weaving and knitting.

iii) Heat:

The acetate-butyrate-coated metallic yarns can be washed at temperatures as high as 70°C, otherwise delamination occurs at higher temperatures. Mylar coated yarns can be washed at boil and are safe upto 145°C.

Identification:

The following procedure will identify the three standard types of Lurex yarn:

1. Burn yarn sample - butyrate Lurex yarn has a rancid odour.

2. Immerse in isopropyl alcohol - butyrate Lurex (film portion) will dissolve, Lurex MM and Lurex MF are insoluble.

3. Stretch yarn sample - Lurex MM and Lurex MF exhibit a stretch of 120-150%, butyrate Lurex will stretch about 20-30%. The aluminium in Lurex MF fractures (separates) on stretching, the aluminium in Lurex MM does not fracture on stretching.

SUMMARY:

Constantly being designed with new and multiple functionality, it is an exciting time to be a part of the metal fibre industry. Metal fibres can most assuredly help to take textiles into areas they have never been before.

About the Author:

Anita Desai is working as a Senior Lecturer at the Sarvajanik College of Engineering & Technology since June 1997. She is a B.Tech and an M.Tech from the Government S.K.S.J.T. Institute, Bangalore. She is currently pursuing her Ph.D. from the Central Silk Technological Research Institute, Central Silk Board, Ministry of Textiles, Government of India, Bangalore.

She has to her credit over 30 research and review publications and presentations at both, the national and international level. Her biographical profile has been included in the premier edition of Marquis Who’s Who in Asia – 2007. She can be contacted on: aap_desai@yahoo.co.in

REFERENCE:

1. Handbook of Textile Fibres - Man-made Fibres, J.Gordon Cook, Merrow Pub.Co., 1984.

2. Identification of Textile Materials, Seventh Edition, The Textile ln Manchester, 1985.

3. Man-Made Fibres, R.W.Moncrief, Newnes Butterworths, London, 1975.

4. Encyclopaedia of Textiles, Prentice-Hall Inc.,USA, 1980.

5. Man-Made Textile Encyclopedia, Interscience Publishers Inc., New York, 1959.

6. Knitting International, June 2001, P. 108-113.

7. Coated textiles principles and application , A.K.Sen, P. 192-201.

8. MANTRA Bulletin, October 1999, P. 1-6.

9. MANTRA Bulletin, November 1999, P. 8-11.

10.Chemical fiber International,Volume 40,November 1997, P. 59-61.

11.Sabit Adanur, Wellington Sears, Handbook of Industrial textile,1995. P 462-463.

12. www.lurex.com

To read more articles on Textile, Industry, Technical Textile, Dyes & Chemicals, Machinery, Fashion, Apparel, Technology, Retail, Leather, Footwear & Jewellery, Software and General please visit http://articles.fibre2fashion.com

To promote your company, product and services via promotional article, follow this link: http://www.fibre2fashion.com/services/article-writing-service/content-promotion-services.asp

Modern metallic fibres of the multi-component type are based largely on aluminium, which provides sparkle, and glitter at fraction of the cost of the early types of decorative fibre based for example, on gold.

The aluminium in these fibres is in the form of a narrow ribbon-filament of either (a) metal foil, or (b) a plastic film which has been vacuum-plated with vaporized aluminium. This is coated with a layer or layers of plastic film. distort

In these composite structures, the metal is protected from corrosive influences of its environment, and from mechanical damage. Multicomponent metallic fibres have achieved great popularity as decorative fibres and are an in facet of the modern textile industry.

TYPES OF METALLIC (M.C.) FIBRE

Metallic (m.c.) fibres may be made in almost infinite variety by using different metals and plastics in their manufacture. Aluminium is, however, the metal most commonly selected, and it is sandwiched between cellulose acetate butyrate, cellophane (cellulose) or polyester films.

The following are the types of yarn commonly produced:

(1)Acetate Butyrate, Aluminium Foil: A continuous flat monofilament composed of aluminium foil laminated on both reflective surfaces with cellulose acetate butyrate film.

(2) Cellophane Aluminium Foil: A continuous flat monofilament composed of aluminium foil laminated on both reflective surfaces with Cellophane film.

(3)Polyester, Aluminium Foil: A continuous flat monofilament composed of Aluminium foil laminated on both reflective surfaces with polyester film.

(4) Polyester, Aluminum Metallized Polyester: A continuous flat monofilament composed of aluminium metallized polyester laminated on its metallized surface or surfaces with polyester film.

(5) Polyester, Aluminium Metallized, Non-Laminated: A continuous, flat monofilament composed of a single layer of aluminium metallized polyester protected on its metallized surface.

The acetate butyrate types of metallic fibre are best used for applications which are not subjected to wet processing of other than very mild forms. Polyester types will withstand wet treatments or dry-heat operations as commonly used with most man made fibres, but reference should be made to manufacturer’s recommendations regarding time, pH and temperature conditions.

NOMENCLATURE AND TERMINOLOGY

In the U.S., the former Metallic Yarns Institute established minimum quality standards for metallic (m.c.) yarns for textile purposes, and prescribed a standard system of designation and terms of reference for these yarns.

The following definition of a metallic yarn was established by the Institute, and in general it is still in common use:

Metallic Yarn: A continuous flat monofilament produced by a combination of plastic film and metallic component so that the metallic component is protected.

Terminology

Metallic yarns are designated by a group of three symbols, each separated by a hyphen, setting forth the two dimensions of width, and gauge or thickness, and generic type.

1. Width. The width of the yarn is expressed as the fraction of an inch to which the yarn has been cut, viz., 1/32, 1/64, etc.

2. Gauge (or Thickness). The thickness or gauge of the yarn is expressed as the sum of the thickness of the plastic film and metallic component in hundred-thousand of an inch, as a whole number, viz., 35, 50, 150, 200, etc.

3. Generic Type. The type of the yarn is expressed on the basis of two components of the laminate - the generic name of the plastic film and the metal.

The components are separated by a comma, viz., Polyester, Foil.

Example: A Polyester/Aluminium Foil Yarn, 1/64 inch wide and 150/100,000 inch thick, is expressed in the industry as:

A manufacturer’s trade name or mark may accompany, but where utilized, either alone or in combination, the above must be separately stated or referred to.

STRUCTURE AND PROPERTIES

The properties of a metallic (m.c.) fibre depend upon the nature of the plastic film used in its production, and of the metal used as the centre of the sandwich.

In general, the fibres behave in a manner similar to man-made fibres spun from polymer on which the plastic film is based. Acetate butyrate metallic filaments, for example, have a resemblance to acetate fibres; polyester type metallic filaments are similar to polyester fibres in their general characteristics.

The nature of the aluminium layer inside the sandwich affects the properties of the metallic filament to a significant extent. In Types 1, 2 and 3, the aluminium is a continuous layer of foil; in Types 4 and 5, on the other hand, it is in the form of discrete particles which have been deposited on a layer of plastic film. The discontinuous layer of the latter type results in a finer, softer and more pliable filament which differ in many respects from those of the foil-type metallic fibres as indicated below. The figures quoted refer to specific metallic fibres of the various basic types, but there is considerable variation in properties between fibres of the same type.

Fine Structure and Appearance:

Metallic (m.c.) fibres are flat, ribbon-like filaments, commonly 3.2-0.2 mm (1/8-1/128 in) width. They are smooth-surfaced, and may be coloured or uncoloured.

Tenacity:

Acetate Butyrate, foil: 2.6 cN/tex (0.3 g/den).

Polyester, foil: 6.2 cN/tex (0.79 g/den).

Polyester, metallized: 11.0 cN/tex (1.25 g/den).

Elongation:

Acetate Butyrate, foil: 30 percent.

Polyester, foil: 140 percent.

Polyester, metallized: 140 percent.

Elastic Recovery:

Acetate Butyrate, foil: 75 percent at 5 percent elongation.

Polyester, foil: 50 percent at 5 percent elongation.

Polyester, metallized: 100 percent at 5 percent elongation.

Flex Resistance:

Relative flex resistances of the main types are in the following ratios:

Acetate Butyrate, foil: 1

Polyester, foil: 18

Polyester, metallized: 70

Abrasion Resistance:

Acetate Butyrate, foil: fair.

Polyester, foil: good.

Polyester, metallized: excellent.

Effect of Moisture Regain:

Acetate Butyrate, foil: 0.1 per cent. Polyester, foil: 0.5 per cent.

Polyester, metallized: 0.25 per cent.

Thermal Properties:

Softening point: Acetate Butyrate, foil: 205°C.

Polyester: 232°C.

Effect of Age:

Nil.

Effect of Sunlight:

Some loss of strength on prolonged exposure.

Chemical Properties:

Acids

Generally good resistance.

Alkalis

Acetate Butyrate: good resistance to weak alkalis; degraded by strong alkalis.

Polyester: these also show similar characteristics. Metal foil types are more resistant.

General

Acetate Butyrate: Similar to acetate yarn. Not affected by sea water, chlorinated water, or perspiration. Generally resistant to bleaches, but sensitive to caustic soda used in peroxide bleaching. Also sensitive to copper sulphate and sodium carbonate at high temperatures.

Polyester: Generally good resistance.

Effect of Organic Solvents

Acetate Butyrate: Attacked by acetone, ether, chloroform, methyl alcohol, tetrachloroethane. Not attacked by benzene, carbon tetrachloride, ethyl alcohol, perchloroethylene, trichloro ethylene.

Polyester: Attacked by acetone, benzene, chloroform, tetra chloroethane, trichioroethylene. Not attacked by carbon tetra chloro ethyl alcohol, methyl alcohol, perchloroethylene, white spirit.

Insects

Not attacked.

Micro-organisms

Not attacked.

Electrical Properties

Metallic (m.c.) fibres conduct electricity - the metallized types having a lower conductivity than the foil types.

METALLIZED (M.C.) FIBRES IN USE

General Characteristics

Appearance:

Metallic (m c) yarns are used in the industry almost entirely as decorative materials. They provide a metallic, g1itter and sparkle that cannot be obtained in other ways. The aluminium foil that provides the glitter in a modern metallic yarn is protected from corrosive materials of its environment by the plastic film in which it is enclosed. It remains untarnished through long periods of wear, and polyester types will withstand repeated launderings without losing their sparkle. Metallic yarns are not affected by sea water or by the chlorinated water of swimming pools and are widely used in modern swimwear.

The dyestuffs used in colouring metallic fibres are usually fast to light and the colour remains bright to match the sparkle from the aluminium foil.

Mechanical Properties:

As metallic (m.c.) yarns are used primarily for decorative purposes, they do not as a rule contribute significantly to the strength of fabrics or garments. Nevertheless they may be used as weft or warp yarns, and are strong enough to withstand the weaving, and knitting operations. If necessary the metallic yarns are combined with support yarns, such as nylon. The plastic film of the metallic yarn is flexible, and the yarns are extensible to a degree that depends upon the type.

Chemical Properties:

Aluminium will corrode and tarnish in air, and in contact with seawater, but in metallic fibres it is protected so effectively that it retains its glitter for long periods. The chemical resistance of a metallic filament is, in general, the chemical resistance of the plastic film. In the case of polyester films, this is outstanding.

If metallic fibres are held in contact with strong alkaline solutions for prolonged periods, the aluminium may be attacked at the unprotected edges of the ribbon. Metallic fibres should not, therefore, be subjected to alkaline reagents of significant strength.

Organic solvents, too, may attack the laminate adhesive or lacquer coating; great care should be taken in dry cleaning to ensure that an appropriate type of solvent is used.

Thermal Properties:

The plastic films in metallic fibres are thermoplastic, and will soften at elevated temperatures. Delamination may occur if the fibres are heated, and acetate types in particular should be processed only at low temperatures.

The plastic film may be permanently embossed by heat and pressure, and special effects may be introduced into the fibres in this way.

Washing:

Acetate butyrate types may be hand washed in lukewarm water with a mild soap. If processed as silks or woollens, they may be safely washed in home or commercial laundry equipment.

Polyester types may be washed at temperatures up to 70°C. Dimensional stability is good and crease resistance is fair.

Most coated polyester yarns will not withstand treatments other than those used for silks or woollens.

Drying:

Acetate butyrate types must be dried at as low a temperature as possible. Polyester types may be dried at higher temperatures as used for polyester fibres, with the exception of most coated types.

Ironing:

Acetate types should be ironed at temperatures no higher than 105°C. Polyester types may be ironed at temperatures up to 130°C. Rayon setting is preferable for both types.

Dry Cleaning:

Metallic fibres may be dry cleaned without difficulty, provided care is taken in the selection of solvent to suit the type of fibre.

End uses: Metallic (m.c.) yarns are used for decorative purposes in almost every field of textile application. Important end-uses include women’s dress goods, upholstery, curtains, table linens, swimwear, packaging, footwear, car upholstery, suits and hats.

MANUFACTURING PROCESS OF METALLIC YARN

Extrusion And Metal Coating

The incorporation of metal into textiles dates back to the Roman era, when they were mainly used for decorative purposes. The tinsel yarns used to add glitter to fabrics were made by flattening thin wire or sheets of noble metals like gold or silver. By the 1930s, aluminium foil strips coated on both sides by cellulose acetate-butyrate, to prevent them from tarnishing, were used. The yarn could be colored by anodizing. All of these yarns had poor compatibility with the more flexible and extensible textile yarns. After the development of vapor-deposited aluminized polyester in the 1960s, 1 mm wide strips of these films were used as yarns, with much improved flexibility.

The American made yarns can best be described as a ham sandwich. The metal foil, metallised pigment and colouring matter might be considered the meat. The meat is placed between two layers of transparent plastic film. The adhesive used between layers to bind all the layers together into one film might be compared to the butter that holds the bread and meat together.

The raw material is a roll of aluminium foil of 0.00045 inch thickness and 20 inch wide. To both sides of the sheet is applied a thermoplastic adhesive to which has already been added the required colouring matters. The adhesive-coated foil is heated to about 90-95°C, and a sheet of cellulose acetate-butyrate transparent film is laminated to each side of the foil by passing through squeeze rollers at a pressure of 2000 lb/in (Fig. I). The laminated material is then slit into filaments of the required width, the most popular width being 1/64 inch although other sizes from 118 inch to 1/120 inch are also made.

The nature of the adhesive that is used is important and not usually disclosed. Gold is the most important colour which is produced by the addition of an orange-yellow dyestuff to the adhesive. Silver is simply the colour of the aluminium itself. Other colours such as bronze, peacock blue and red are obtained by using the suitable pigment. Multi-coloured efects, e.g. red and green alternating irregularly along the length of the yarn, are obtained by pre-printing the plastic film and laminating in the usual way.

METHODS OF METAL COATING

A. Metal coating with a binder:

The process is similar to conventional polymer coating. High leafing aluminium pastes (65-70%) are incorporated into a polymeric carrier, like synthetic rubber, PVC, polyurethanes, silicones, acrylic emulsions, etc., and spread coated on the fabric. The coating method may be conventional knife or roller coating. The adhesion, flex, and chemical resistance of the coated fabric depend on the type of polymer used, but they are not highly reflective.

B. Vacuum deposition:

In this process, the substrate to be coated is placed in a chamber over a set of crucibles containing the metal to be coated in the form of a powder/wire. The chamber containing the whole assembly is evacuated to 0.5-1 torr. The crucible is heated by resistance heating to melt the metal. The temperature of heating is so adjusted that the vapour pressure of the metal exceeds that of the chamber pressure, so that substantial evaporation of the metal takes place. The temperature required for aluminium is about 1200ºC. The roll of web to be coated is passed over a cooled drum placed over the crucibles. The metal atoms coming out of the molten metal hit the surface of the web to be coated and condense in the form of solid metal as it passes over the crucible. The production speed is quite high, ranging from 150-500 m/min. The items to be coated should be pretreated for proper adhesion of the metal. Continuous metal film coatings can be formed on just about any surface, film, fiber or fabric with thickness ranging from micron to millimeter. Several metals can be vacuum evaporated, most common being aluminium, copper, silver, and gold. Difficulty arises in the case of metals, which sublime rather than melt and boil.

C. Sputter coating:

The equipment consists of a vacuum chamber containing an inert gas, usually argon, at 10-3 to 10-1 torr. The chamber is equipped with a cathode (target), which is the source of the coating material, and an anode, which acts as a substrate holder. Application of an electrical potential of the order of 1000 VDC, between the two electrodes, produces a glow discharge. A flow of current occurs due to movement of electrons from cathode to anode. The electrons ionize the argon gas. The argon ions are accelerated toward the cathode at a high speed due to high electric potential. The bombardment of the energetic ion on the target results in a transfer of momentum. If the kinetic energy of the striking ion is higher than the binding energy of the surface atoms of the material of the target, atoms are dislodged or sputtered from its surface by a cascade of collisions. Typically, the threshold kinetic energy of the ions should be between 10-30 EV for sputtering from the surface. Some of the ions striking the target surface generate secondary electrons. These secondary electrons produce additional ions, and the discharge is sustained. Considerable heat is generated during the sputtering process, and it is necessary to cool the target. The sputtered atoms and ions condense on the substrate to form a thin film of coating. The relative rates of deposition depend on sputter yield, which is the number of atoms ejected per incident ion. The sputtering yield varies with the target material and increases with the energy of the incident ion. The method is applicable to a wide range of materials and gives more uniform coating with better adhesion than simple vapour deposition. The process is however, more expensive, and the rate of deposition is lower (30 m/min)

D. Electroless plating:

It is a process to deposit metal film on a surface, without the use of electrical energy. Unlike electroplating where externally supplied electrons act as reducing agent, in electrodes plating, metallic coatings are formed as a result of chemical reaction between a reducing agent and metal ions present in solution. In order to localize the metal deposition on a particular surface, rather than in the bulk of the solution, it is necessary that the surface should act as a catalyst. The activation energy of the catalytic route is lower than the homogeneous reaction in solution. If the deposited metal acts as a catalyst, autocatalysis occurs, and a smooth deposition is obtained. Such an autocatalytic process is the basis of electroless coatings. Compared to electroplating, electroless coating has the following advantages:

(l) Nonconducting materials can be metallized

(2) The coating is uniform.

(3) The process is simple and does not require electrical energy

Electroless coating is, however, more expensive.

For successful deposition of coatings, only autocatalytic reduction reactions can be used. As such, the numbers of metals that can be coated are not many. Some of the common reducing agents are sodium hypophosphite, formaldehyde, hydrazine, and organo boron compounds. Each combination of metal and reducing agent requires a specific pH range and bath formulation. The coating thickness varies between 0.01 um to 1 mm.

A typical plating solution consists of

a. Metal salt

b. Reducing agent

c. Complexing agents, required in alkaline pH and also to enhance the autocatalytic process

d. Buffers

e. Stabilizers, which retard the reaction in the bulk and promote autocatalytic process.

Some important metal coatings are discussed below:

a. Copper:

The most suitable reducing agent is formaldehyde. The autocatalytic reaction proceeds in alkaline pH (11-14). The commonly used complexing agents are EDTA, tartarate, etc.

b. Nickel:

Sodium hypophosphite is the most popular reducing agent for nickel. The autocatalytic reaction occurs in both acidic and alkaline pH. Sodium citrate is used as buffer and complexing agent. The coating obtained by sodium phosphite also contains phosphorus (2-15%).

c. Silver:

The plating solution consists of ammoniacal silver nitrate with formaldehyde, hydrazine, and glucose as reducing agents. Because the autocatalytic activity of silver is low, thick deposits cannot be obtained. Electroless plating of textiles is being adapted for different functional applications.

SLITTING OPERATION

The slitting operation involves the two main types of cutting by which a metallised polyester film is converted into the tape filaments:

(a) Rough Slitter

(b) Micro Slitter

The metallized polyester film supplied to the slitting operation has the following parameters:

(1) Thickness: Normally ranges between 12 to 25 Microns.

(2) Length: Sheet in the form of roll having the length from 5000 to 10,000 meters.

(3) Width: The width of the sheet ranges between 510mm to 1000mm.

ROUGH SLITTER

his slitter cuts the large polyester sheet into Pancakes. The width of the each Pancake is 54mm. In addition side strips of 2mm are kept extra on each side. Thus the resultant width of the pancake is 58mm.

Cutters of different size are used for this operation, for example 0.2mm, 0.23mm, 0.25mm, 0.30mm, 0.376mm, etc. Pancakes are also in the form of rolls supplied to the Micro Slitter.

MICRO SLITTER

The Micro Slitter is a general name given to both slitter and winder for producing the yarn 0.15mm -1 mm wide.

In this operation Pancakes are converted into numbers of tape filaments. It has two main parts,

(a)Cutting Mechanism

(b) Winding Mechanism

Cutting of Pancakes and Winding of tape filaments are carried out simultaneously.

The cutting mechanism consists of two parallel shafts. On each shaft blades are mounted side by side such that the edge of one blade on one shaft slightly touches the edge of the blade mounted on the other shaft. The cutter is mounted on to the shaft with the help of Separator and Support Ring. The width of the tape filament decides the width of the cutter.

The winding mechanism consists of number of winding positions. The winder is driven by a separate motor. The traverse mechanism is also provided for obtaining the parallel wound package. The speed of the winder is 2.5% to 5% higher than that of the cutter.

COVERING MACHINE

Nowadays machines can produce a high quality of covering yarns for even 200, 300, denier of polyester yarn, cotton and even silk, which is applied to stocking, socks and particularly woven elastic fabrics.

The important characters of the machine are the balance and the alignment of spindles and guide rollers. It is well designed for flexibility and anti-wearing by using good quality of materials to each part of character. The specification of machine can be changed according to a pitch and number of spindles.

GENERAL APPLICATION

Metallized products are used in industrial, specialty and protective clothing applications. There are various ways to combine metals with textile materials for specific applications.

Metallized fabrics provide good abrasion resistance, reflectivity over extended time, wear resistance and molten metal splash resistance.

Coating/Laminating

Textile fabrics are used as substrates in metallized protective materials. Woven, knit and nonwoven fabrics may be coated or laminated with metal surfaces. Substrate fabrics can be made of aramids, carbon based fibers, PBI, glass, cotton, rayon and others. Aluminum is widely used in metallized fabrics.

In aluminized fabric, aluminum molecules are deposited on a PET film. Examples are Mylar from DuPont and Hostaphana from Hoechst. The aluminized film can reflect up to 90% of radiant heat. Gold can be used for reflection of up to 100%, but it is expensive.

Laminated metallized fabrics can be made of several layers of materials. A typical five-ply dual mirror

aluminized fabric has the following layers: aluminum, protective film, a second layer of aluminum, heat stable adhesive and fabric.

Blending

Metal sliver can be blended with synthetic or natural fibers to produce conductive textiles. Stainless steel sliver used for this purpose usually has 4.8 or 12 micron fiber diameters and weighs approximately 1.2 or 4 grams. The fiber length may vary from 1.5 to 6 inches. There are several methods to produce metal fibers including bundle drawing (most common), wire drawing, shaving, shearing, melt spinning, melt extracting and stretch casting. For maximum conductivity, the steel fiber is introduced at the last drawing operation. Protective fabrics made from metal-based blended fibres are suitable to protect individuals from the hazardous effects of electrostatic discharge and electromagnetic radiation.

Composite Yarns

Multi-filament metal fibre yarns can be twisted or wrapped with textile yarns to produce composite yarns. These yarns are suitable for cut resistant apparel items, antistatic brushes for business machines, lightning strike protection and antistatic filter bags. The most widely used metal yarns are 12 microns/91 filaments, 25 microns/91 filaments.

Nonwoven Metal Based Fabrics

Chopped metal fibres can be air or wet laid with textile fibers to form nonwoven textiles. For air layering, 1 inch fiber length and 4-38 micron fiber diameters are used. For wet layering, fiber lengths of 0.125 to 0.5 inch have been successfully used. Binders or sintering may be used for stabilization. During sintering, the organic binder fibers are burned off, leaving a 100% metallic fiber structure. In general, fiber diameters of 4-15 microns in 0.125-0.250 inch lengths are suitable for this process

Test methods and characteristics to evaluate the metallized products include the following:

• Military Specification, MIL-C-87076A, for Aluminized, Twill Weave, Aramid, Coated Cloth

• MIL-C-24924A Class I (fire proximity garments)

Applications in technical textiles:

Following Attributes of fibres make them suitable for applications in technical textiles:

• Electrical Conductivity

• Electro Magnetic Shielding

• Anti-Microbial

• Heat Resistance

• Strength

•Chemical Reactivity

• Corrosion Resistance

• Flexibility (compared to wire or steel wool textile structures)

• Weldability

Existing and Potential Applications:

Given the above product characteristics, some existing and potential applications are as follows:

Existing Applications:

1 Anti-static protective clothing garments in the Petro-chemical, pilot suits, fire workers suits, etc.

a. Anti-static fabric panels for garments

b. ESD shoe soles and Overshoes

c. Sewing threads for connection of fabric panels for improved sleeve-to-sleeve

ESD compliance.

2. Shielding fabrics for utility workers in high field areas.

3. Muscle stimulation electrodes.

4. ESD Brushes.

5. Bulk container bags for powders and pellets.