Today, more than 60 per cent of textile fibres, such as polyester fibres (PES) and polyamide fibres (PA), are made from plastic using petrol-based materials. Market prices of these materials are low and do not reflect the negative impact of these materials on the environment.

Plant-based, cellulosic materials, such as cotton, represent one-third of the fibre market and the demand for these materials is growing as they do not contribute to microplastics. However, the performance and versatility of these cellulosic materials is limited, and production is not scalable.

AMSilk’s bio-fabricated silk materials use carbon from plants. Using biotechnology and microorganisms, the production of our materials transforms the plant-based carbon into complex proteins. For AMSilk, it started with spider silk proteins, however, our technology platform offers the option to design the properties of our proteins for different applications. This allows us to bridge the gap between smart performance and sustainability.

AMSilk’s technology has created a unique class of plant-based materials, which we are beginning to make available in significant industrial quantities. As we begin to scale up our production, AMSilk’s goal is to make smart performing biotech materials part of everyday life, providing alternatives to the conventional materials mentioned above.

The general concept of biomaterials and bio-fabrication has widely established itself in recent years as technology provides sustainable alternatives and smart performing solutions for the future.

Our customers and partners love to work with a material made from plant-based renewable raw materials, which are 100 per cent biodegradable, recyclable and microplastic free.

As we transition to a zero-waste society, there is an ever-increasing demand for sustainable alternatives. Seeing the current size of the market, investments in biotechnology and economy of scale from bigger production volumes, we expect that the growth will be exponential.

Within our current focus, we have identified a huge potential market of more than €30 billion where existing materials are waiting for true innovation. Therefore, at this stage we do not yet talk about significant market shares.

At present, Europe and Asia are our major market for textiles, and Europe and the US for the other sectors.

AMSilk started with the idea to make spider silk, which is the strongest natural material in the world (2.5 times stronger than steel) and extremely versatile, available in industrial quantities.

During this process, we discovered that silk proteins are scalable at the molecular level. This means we can change the properties of our silk proteins so that they can be tailor-made to the targeted application.

In the future, our materials have the potential to be utilised in a number of industries.

AMSilk has identified more than 50 potential applications and it is wonderful to have such a powerful technology platform that has the potential to provide long-term solutions in a number of sectors.

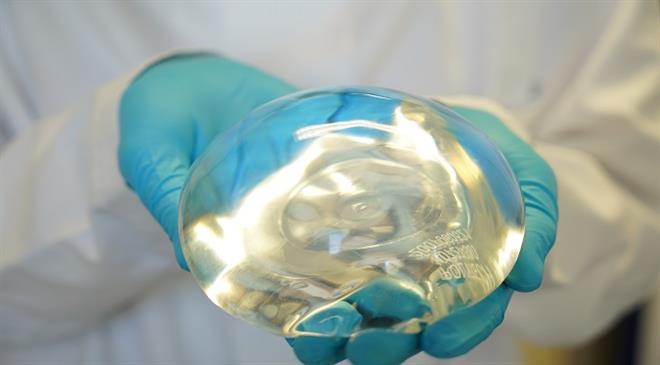

As we scale up our business, we have to keep focus on selected applications including textile fibres for apparel and performance footwear, medical devices and consumer goods.

We have been working with the world’s leading brands in the automotive sector like Mercedes-Benz, for the car manufacturer’s latest technology programme, the VISION EQXX. As well as for brands in the premium apparel and medical aesthetics sectors, and we will see commercial products in the market in 2023.

We enable our customers to make a change in their industries by making biotech materials accessible to everyone. Being in line with our sustainability goals but also considering the latest happenings in international supply chains and trade, it is clear to us that we will be close to our customers and locally supply their demand.

We will first scale up in Europe—and have started to increase our production capacity beyond several thousand tons a year—and then extend our production network outside of Europe.

Based on our scalable biotechnological platform and a world class patent portfolio, we can provide large quantities of premium bio-fabricated silk materials in consistent quality. This will be our contribution towards making smart biotech materials a part of everyday life.

As with all true innovations, the cost of truly innovative biomaterials will initially be higher compared to traditional fossil products and chemical supply chains. We believe that over the next two years, the main topic for the bioindustries is how to scale up and commercialise these innovations to overcome this cost gap over time.

To achieve successful scale-up, in addition to fantastic biomaterials and world-class scientists, you also need a team of experienced professionals with commercial competence as well as a very strong and diverse shareholder structure. We at AMSilk have worked very hard over the last two years to create these conditions.

We have a strong platform now and believe our products can make a valuable contribution to the transition to a better future.

DISCLAIMER: All views and opinions expressed in this column are solely of the interviewee, and they do not reflect in any way the opinion of technicaltextile.net.